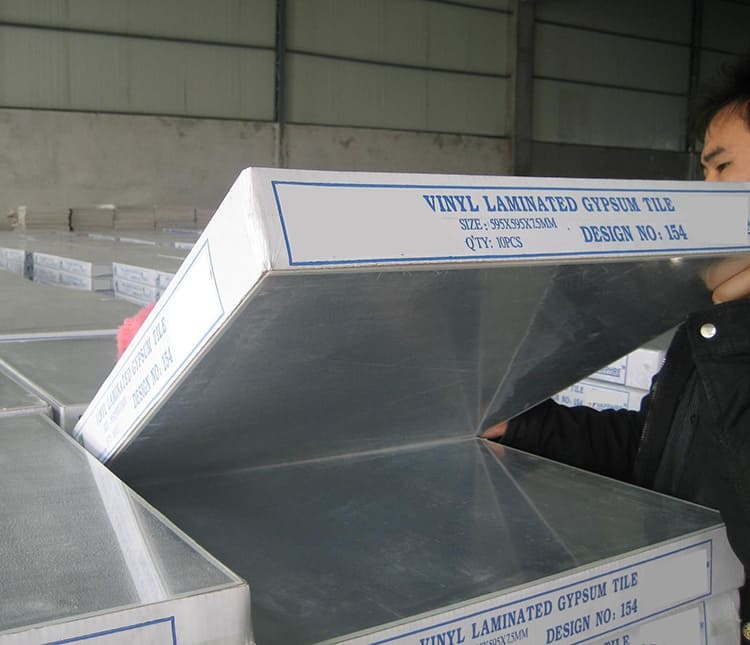

PVC gypsum ceiling tiles and PVC aluminum foil ceiling systems achieve waterproofing through surface sealing, installation with moisture barriers, joint treatment using waterproof sealants, and integration with ventilation systems for comprehensive moisture and humidity management. These principles apply similarly to gypsum ceiling panels and gypsum ceiling installations where controlled moisture resistance and long-term durability are required.

Surface preparation for PVC gypsum ceiling tile and gypsum ceiling panel applications requires thorough cleaning and priming with moisture-blocking primer applied in two coats. Joint sealing between individual PVC gypsum ceiling tiles or PVC aluminum foil ceiling boards uses a flexible waterproof sealant rated for bathroom and kitchen environments. Moisture barrier installation behind gypsum ceiling panels includes 6-mil polyethylene sheeting with sealed overlaps to prevent vapor intrusion. Proper ventilation integration for gypsum ceiling systems prevents condensation buildup through exhaust fans rated at 1 CFM per square foot, maintaining stable humidity levels. Regular maintenance includes annual inspection of seals, joints, and surface integrity for long-term waterproof performance of the PVC gypsum ceiling tile system.

From my extensive experience in PVC-faced gypsum board manufacturing, I’ve observed that effective waterproofing in both PVC gypsum ceiling tiles and PVC aluminum foil ceilings requires systematic integration of material properties, installation techniques, and environmental controls rather than relying solely on surface treatments.

Does Tin Foil Stop Damp?

Tin foil can serve as a vapor barrier for PVC gypsum ceiling tile and gypsum ceiling panel installations, reducing moisture transmission but not eliminating dampness sources. Effective design of PVC aluminum foil ceiling systems requires proper installation and ventilation for humidity and condensation control.

Aluminum foil provides 99.9% vapor barrier efficiency when properly installed with sealed joints and overlaps, helping maintain moisture protection for PVC gypsum ceiling tile ceilings. Moisture transmission rate drops near zero through continuous foil membranes without punctures, but condensation risk rises on cold surfaces unless insulation supports the gypsum ceiling panel structure. Installation requirements include 50–100mm overlaps at joints, sealed with aluminum tape. Ventilation systems remain essential for managing moisture buildup beneath PVC aluminum foil ceiling assemblies.

Vapor Barrier Performance Characteristics

| Performance Parameter | Aluminum Foil | Plastic Sheeting | Building Paper | Specialized Membranes |

|---|---|---|---|---|

| Vapor Permeability | <0.01 perms | 0.05–0.1 perms | 1–5 perms | 0.1–1 perms |

| Durability | Excellent | Good | Fair | Excellent |

| Installation Ease | Moderate | Easy | Easy | Moderate |

| Cost Factor | Medium | Low | Low | High |

| Temperature Range | -40°C to 200°C | -20°C to 60°C | -10°C to 80°C | -30°C to 150°C |

Aluminum foil offers superior vapor barrier performance, making it a key component in PVC aluminum foil ceiling and PVC gypsum ceiling tile moisture control systems.

Installation Requirements

Proper installation ensures the vapor barrier functions effectively within gypsum ceiling panels and PVC gypsum ceiling tile assemblies.

| Installation Factor | Specification | Critical Points | Common Errors | Quality Control |

|---|---|---|---|---|

| Joint Overlap | 50–100mm | Continuous seal | Insufficient overlap | Tape test |

| Sealing Method | Aluminum tape | Weather resistance | Standard tape use | Peel test |

| Surface Preparation | Clean, dry substrate | Adhesion quality | Dirty surfaces | Visual inspection |

| Puncture Prevention | Careful handling | Membrane integrity | Tool damage | Light test |

| Edge Sealing | Complete perimeter | Thermal bridge prevention | Gap allowance | Smoke pencil |

High-quality joint sealing between gypsum ceiling panels and PVC gypsum ceiling tiles determines overall vapor barrier effectiveness.

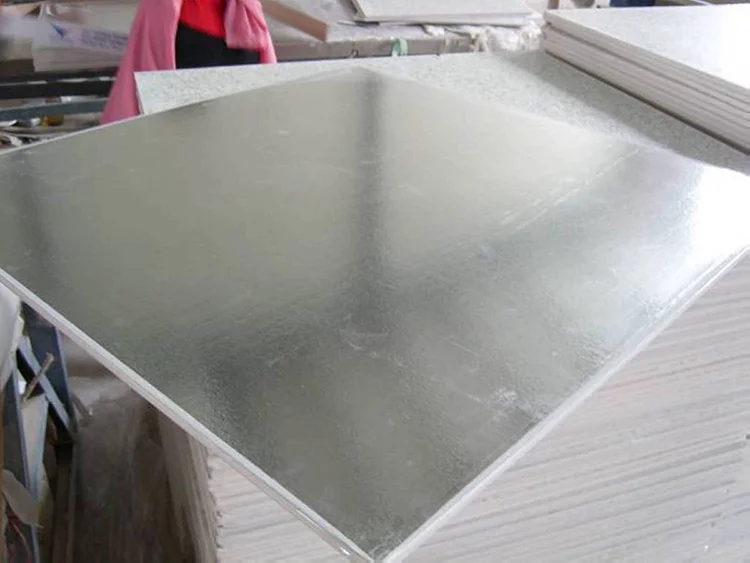

Is Foil Waterproof?

Aluminum foil is water-resistant, not technically waterproof. In PVC aluminum foil ceiling applications, it provides an excellent moisture vapor barrier but requires proper sealing and installation to achieve durable water-resistant performance.

Aluminum foil resists liquid water penetration when installed continuously behind PVC gypsum ceiling tile panels without damage. Punctures or tears compromise water resistance; hence seam sealing with aluminum tape is critical. Under hydrostatic pressure beyond 1–3 PSI, leaks may appear at poorly sealed joints. Long-term performance in gypsum ceiling environments demands protection against mechanical damage and UV degradation.

Water Resistance Testing Results

| Test Parameter | Performance Result | Testing Standard | Pass/Fail Criteria | Real-World Implications |

|---|---|---|---|---|

| Liquid Water Penetration | None | ASTM E331 | Zero leakage | Surface water resistance |

| Hydrostatic Pressure | 1–3 PSI failure | ASTM D751 | Variable limits | Limited submersion |

| Tear Propagation | 200–500g force | ASTM D1004 | Material dependent | Installation sensitivity |

| UV Degradation | 6–12 months | ASTM G154 | Visible deterioration | Protection required |

| Thermal Cycling | Minimal effect | ASTM D6944 | No cracking | Temperature stable |

Sealing System Requirements

When using aluminum foil-faced gypsum ceiling panels or PVC aluminum foil ceiling tiles, a comprehensive sealing system ensures water resistance.

| Component | Specification | Application | Lifespan | Maintenance |

|---|---|---|---|---|

| Aluminum Tape | 50–75mm width | Pressure applied | 10–15 years | Annual inspection |

| Butyl Sealant | Weather-grade | Bead applied | 15–20 years | Reseal every 5 years |

| Mechanical Fasteners | Corrosion-resistant | Specified spacing | 20+ years | Tightness check |

| Edge Termination | Flashing integration | Professional install | 20–25 years | Storm damage check |

| Penetration Sealing | Compatible materials | Custom application | 10–15 years | Regular monitoring |

Performance Limitations

| Limitation Factor | Impact Level | Mitigation Strategy | Cost Implications | Success Rate |

|---|---|---|---|---|

| Mechanical Damage | High | Protection layers | 20–40% cost increase | 85–95% |

| Installation Quality | Critical | Professional installation | 10–25% increase | 90–98% |

| Thermal Movement | Medium | Flexible connections | 5–15% increase | 95–99% |

| Corrosion Potential | Low | Compatible materials | Minimal increase | 98–99% |

| UV Exposure | High | Cover materials | 15–30% increase | 90–95% |

Protecting PVC gypsum ceiling tiles and gypsum ceiling panels from mechanical wear represents the most significant performance factor.

Does Foil Insulation Stop Condensation?

Foil insulation, especially within PVC aluminum foil ceiling assemblies or foil-backed gypsum ceiling panels, helps reduce condensation by reflecting radiant heat and forming an effective vapor barrier. Proper installation with air gaps and ventilation systems enhances its condensation control effectiveness.

Radiant barrier properties reflect 95–97% of thermal radiation, reducing temperature differentials that cause condensation on PVC gypsum ceiling tiles. Vapor barrier characteristics block moisture transmission (<0.01 perms). Air gaps of 19–25mm maintain reflective performance while preventing thermal bridging in gypsum ceiling systems. Ventilation integration—via exhaust or air circulation systems—removes trapped moisture for sustained control.

Condensation Control Mechanisms

| Control Mechanism | Effectiveness | Operating Principle | Installation Requirements | Performance Factors |

|---|---|---|---|---|

| Radiant Reflection | 85–95% heat reduction | Surface emissivity | Air gap maintenance | Surface cleanliness |

| Vapor Barrier | 99%+ moisture blocking | Impermeable membrane | Continuous sealing | Joint integrity |

| Thermal Break | 60–80% conduction reduction | Air space insulation | Proper spacing | Gap consistency |

| Surface Temperature Control | Variable | Heat retention | Insulation backing | System integration |

| Moisture Interception | Partial | Condensation collection | Drainage provision | Maintenance access |

Installation Requirements for Optimal Performance

| Installation Parameter | Specification | Purpose | Critical Factors | Quality Verification |

|---|---|---|---|---|

| Air Gap Spacing | 19–25mm | Reflective performance | Consistent spacing | Ruler measurement |

| Vapor Seal Continuity | 100% coverage | Moisture barrier | Joint sealing | Smoke test |

| Drainage Provision | 2% slope | Water removal | Management | Flow test |

| Ventilation Integration | 1 CFM/sq ft | Humidity control | Air movement | Velocity measurement |

| Thermal Bridge Prevention | Zero contact points | Heat transfer control | Fastener isolation | Thermal imaging |

Conclusion

PVC gypsum ceiling tiles, PVC aluminum foil ceilings, and gypsum ceiling panels achieve optimal waterproofing through a combination of surface sealing, moisture-blocking primer, waterproof joint treatment, moisture barrier installation, and ventilation integration. Tin foil and aluminum layers act as vapor barriers with 99.9% efficiency when properly sealed, supporting moisture management in gypsum ceiling systems. While aluminum foil is water-resistant rather than fully waterproof, it enhances protection when integrated within PVC gypsum ceiling tile structures. Foil insulation further reduces condensation through 95–97% radiant heat reflection and vapor impermeability (<0.01 perms), provided air gaps (19–25mm) and ventilation are maintained.

In summary, moisture control performance in PVC gypsum ceiling tiles, PVC aluminum foil ceilings, and gypsum ceiling panels depends on integrated design—combining vapor barriers, thermal insulation, ventilation, and professional installation rather than relying on a single component. Systematic approaches yield long-term durability, energy efficiency, and superior moisture resistance.