Z275 galvanized steel studs have a zinc coating weight of 275g/m² providing superior corrosion resistance and longer lifespan compared to standard steel studs with 60-90g/m² zinc coating, making Z275 ideal for high-humidity environments like coastal regions where enhanced rust protection is essential for structural integrity.

Z275 coating designation indicates 275 grams zinc per square meter surface providing enhanced corrosion protection compared to standard 60-90g/m² coatings. Thickness difference affects rust resistance performance with Z275 offering 15-25 years versus 5-10 years for standard coatings. Cost premium for Z275 ranges 20-40% but provides superior value in high-moisture environments. Structural performance remains identical with coating affecting longevity rather than load-bearing capacity. Application suitability makes Z275 optimal for coastal construction and humid climates.

From my extensive experience manufacturing light steel framing systems, I've observed that coating selection dramatically impacts long-term performance in challenging environmental conditions like those found in Caribbean and South American coastal regions.

Why Are My Ceiling T-Grids Rusting, and What is the Best Anti-Rust Replacement?

Ceiling T-grids rust due to inadequate galvanized coating, high humidity exposure, poor ventilation, and moisture infiltration from roof leaks or HVAC condensation, with the best anti-rust replacement being powder-coated aluminum T-grids or heavy-duty galvanized steel with Z275 coating for superior corrosion resistance.

Inadequate coating protection allows moisture penetration through thin galvanized layers causing rust formation at connection points. High humidity environments accelerate corrosion processes especially in coastal areas with salt air exposure. Poor ventilation creates moisture accumulation above ceiling systems promoting rust development. Roof leaks and HVAC condensation introduce direct water contact causing rapid deterioration. Best replacements include powder-coated aluminum offering permanent rust resistance or Z275 galvanized steel providing enhanced protection.

Rust Formation Causes

Multiple environmental and installation factors contribute to ceiling T-grid corrosion.

| Rust Cause | Mechanism | Severity Level | Prevention Method | Occurrence Rate |

|---|---|---|---|---|

| Inadequate Coating | Zinc layer too thin | High impact | Specify Z275 coating | 60-70% of failures |

| Humidity Exposure | Constant moisture | Moderate-High | Ventilation improvement | 50-60% of cases |

| Water Infiltration | Direct water contact | Severe impact | Leak repair | 30-40% of cases |

| Poor Ventilation | Moisture accumulation | Moderate impact | Air circulation | 40-50% of cases |

| Dissimilar Metals | Galvanic corrosion | Variable impact | Material compatibility | 20-30% of cases |

Inadequate coating represents the primary cause of T-grid rust failures.

Anti-Rust Replacement Options

Different replacement materials offer varying levels of corrosion resistance and performance.

| Replacement Type | Corrosion Resistance | Cost Factor | Installation Method | Lifespan | Environmental Suitability |

|---|---|---|---|---|---|

| Powder-Coated Aluminum | Excellent | High (+80-120%) | Standard grid system | 25-30+ years | All environments |

| Z275 Galvanized Steel | Very Good | Moderate (+40-60%) | Standard installation | 20-25 years | High humidity |

| Stainless Steel | Excellent | Very High (+150-200%) | Specialized fasteners | 30+ years | Extreme conditions |

| Vinyl-Coated Steel | Good | Moderate (+30-50%) | Standard methods | 15-20 years | Moderate humidity |

| Painted Galvanized | Fair-Good | Low (+10-20%) | Standard installation | 10-15 years | Dry environments |

Powder-coated aluminum provides optimal corrosion resistance for high-humidity environments.

Performance Comparison

Long-term performance varies significantly between different T-grid material options.

| Performance Factor | Standard Galvanized | Z275 Galvanized | Powder-Coated Aluminum | Stainless Steel |

|---|---|---|---|---|

| Humidity Resistance | 3/10 rating | 7/10 rating | 9/10 rating | 10/10 rating |

| Salt Air Resistance | 2/10 rating | 6/10 rating | 9/10 rating | 10/10 rating |

| Maintenance Requirements | High | Moderate | Low | Very Low |

| Aesthetic Retention | Poor | Good | Excellent | Excellent |

| Cost-Effectiveness | Short-term only | Good value | Excellent value | Premium value |

Powder-coated aluminum delivers superior performance across multiple criteria.

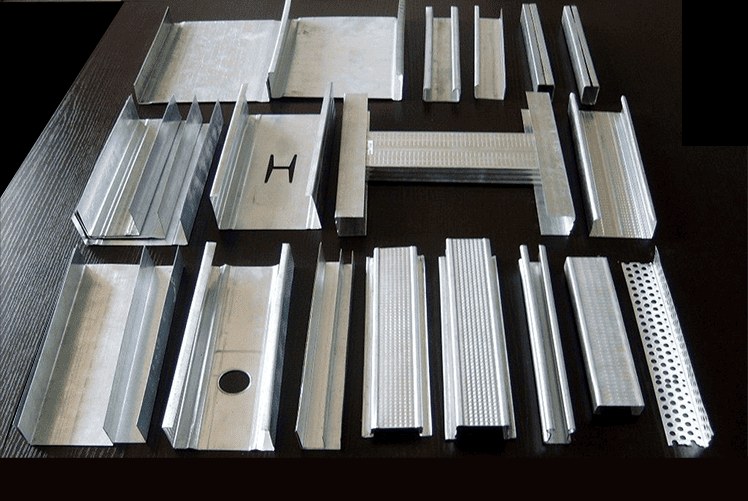

Standard Gauge Thickness for Light Steel Framing Used in Guyana Projects?

Standard gauge thickness for light steel framing in Guyana projects ranges from 0.45mm to 0.75mm, with 0.55mm being most common for partition walls, 0.65mm for load-bearing applications, and 0.75mm for structural elements, selected based on high humidity climate requirements and local building practices.

Partition wall studs typically use 0.45-0.55mm thickness providing adequate strength for non-load bearing applications in residential and commercial construction. Load-bearing applications require 0.65-0.75mm gauge to support structural loads while resisting deflection under tropical climate conditions. Ceiling track systems commonly use 0.45-0.55mm thickness for suspended applications with 0.65mm for heavy ceiling loads. Environmental factors in Guyana's climate favor thicker gauges for enhanced corrosion resistance and structural stability.

Application-Specific Thickness

Different structural applications require specific gauge thickness for optimal performance in Guyana's climate.

| Application Type | Standard Thickness | Load Requirements | Environmental Factors | Performance Rating |

|---|---|---|---|---|

| Partition Studs | 0.45-0.55mm | Non-load bearing | High humidity resistance | Good |

| Load-Bearing Studs | 0.65-0.75mm | Structural loads | Enhanced corrosion protection | Excellent |

| Ceiling Track | 0.45-0.55mm | Suspended loads | Moisture resistance | Good |

| Floor Track | 0.55-0.65mm | Base connection | Ground moisture protection | Very Good |

| Structural Elements | 0.75-1.0mm | Primary loads | Maximum durability | Excellent |

Load-bearing studs require thicker gauge for structural integrity in tropical conditions.

Climate Considerations

Guyana's tropical climate influences gauge selection for long-term performance.

| Climate Factor | Impact on Selection | Recommended Adjustment | Performance Benefit | Cost Implication |

|---|---|---|---|---|

| High Humidity | Corrosion acceleration | Thicker gauge/better coating | Extended lifespan | +20-30% material |

| Temperature Variation | Thermal expansion | Enhanced stability | Reduced movement | +15-25% cost |

| Salt Air (Coastal) | Accelerated corrosion | Premium coatings | Corrosion resistance | +30-40% premium |

| Heavy Rainfall | Moisture infiltration | Sealed connections | Water resistance | +10-15% installation |

| High Winds | Structural loading | Increased thickness | Wind resistance | +25-35% material |

High humidity requires thicker gauge selection for adequate corrosion resistance.

Regional Standards

Local building practices in Guyana reflect climate-adapted specifications.

| Building Type | Common Thickness | Structural Requirements | Local Preferences | Availability |

|---|---|---|---|---|

| Residential | 0.45-0.55mm | Light structural | Cost optimization | Good availability |

| Commercial | 0.55-0.65mm | Moderate loads | Performance balance | Good availability |

| Industrial | 0.65-0.75mm | Heavy structural | Maximum durability | Limited availability |

| Institutional | 0.65-0.75mm | Code compliance | Safety priority | Moderate availability |

| Coastal Projects | 0.65-0.75mm | Enhanced protection | Corrosion resistance | Import required |

Commercial applications represent the most common gauge thickness usage.

Product Specifications

Heavy-duty ceiling suspension systems require specific performance characteristics for commercial applications.

| System Component | Load Capacity | Material Grade | Corrosion Protection | Installation Method |

|---|---|---|---|---|

| Main Tees | 40-60 lbs/linear ft | Heavy-gauge steel | Powder coating | Grid assembly |

| Cross Tees | 30-40 lbs/linear ft | Reinforced steel | Galvanized/painted | Interlocking system |

| Wall Angles | 25-35 lbs/linear ft | Structural grade | Enhanced coating | Perimeter mounting |

| Suspension Wire | 12-gauge minimum | Galvanized steel | Zinc coating | Ceiling attachment |

| Connectors | Engineered capacity | Alloy construction | Corrosion resistant | Mechanical fastening |

Main tees provide primary structural support in heavy-duty suspension systems.

Installation Considerations

Heavy-duty systems require specific installation practices for Georgetown's climate conditions.

| Installation Factor | Standard Practice | Heavy-Duty Modification | Climate Adaptation | Performance Impact |

|---|---|---|---|---|

| Spacing Requirements | 24" centers | 18-20" centers | Reduced spans | Increased capacity |

| Suspension Points | Standard density | Increased density | Enhanced support | Better stability |

| Corrosion Protection | Basic coating | Premium finish | Humidity resistance | Extended lifespan |

| Seismic Considerations | Minimal bracing | Enhanced bracing | Wind resistance | Improved safety |

| Access Provisions | Standard panels | Reinforced panels | Heavy equipment | Maintenance capability |

Reduced spacing provides enhanced load capacity for heavy-duty applications.

Conclusion

Z275 galvanized steel studs feature 275g/m² zinc coating providing superior corrosion resistance compared to standard 60-90g/m² coatings, making them ideal for high-humidity environments with 15-25 year lifespan versus 5-10 years standard. Ceiling T-grids rust due to inadequate coating protection, high humidity exposure, and moisture infiltration, with powder-coated aluminum or Z275 galvanized steel providing optimal anti-rust replacement solutions. Standard gauge thickness for light steel framing in Guyana projects ranges 0.45-0.75mm with 0.55mm common for partitions and 0.65-0.75mm for load-bearing applications adapted to tropical climate requirements. Success with light steel framing systems requires understanding that coating quality dramatically affects longevity, environmental conditions drive material selection, gauge thickness must match structural and climate requirements, and local sourcing requires advance planning for specialized heavy-duty components, making proper specification and supplier selection critical for long-term performance in challenging tropical environments.