Recycled plasterboard is used for manufacturing new gypsum products, agricultural soil amendment, cement production as a setting retarder, paper manufacturing, and road base construction, with the gypsum content being processed into calcium sulfate dihydrate for reuse in various industrial applications.

Manufacturing new plasterboard represents the primary application where recycled gypsum becomes raw material for fresh board production. Agricultural soil amendment uses gypsum's calcium and sulfur content to improve soil structure and reduce sodium levels. Cement production incorporates recycled gypsum as a setting retarder controlling concrete curing time. Paper manufacturing utilizes gypsum as a filler material improving paper quality and reducing costs. Road construction applies processed gypsum in base materials for structural stability.

From my extensive experience in gypsum board manufacturing, I've observed that recycling represents not just waste management but a fundamental shift toward circular economy principles in building materials.

What Happens to Recycled Plasterboard?

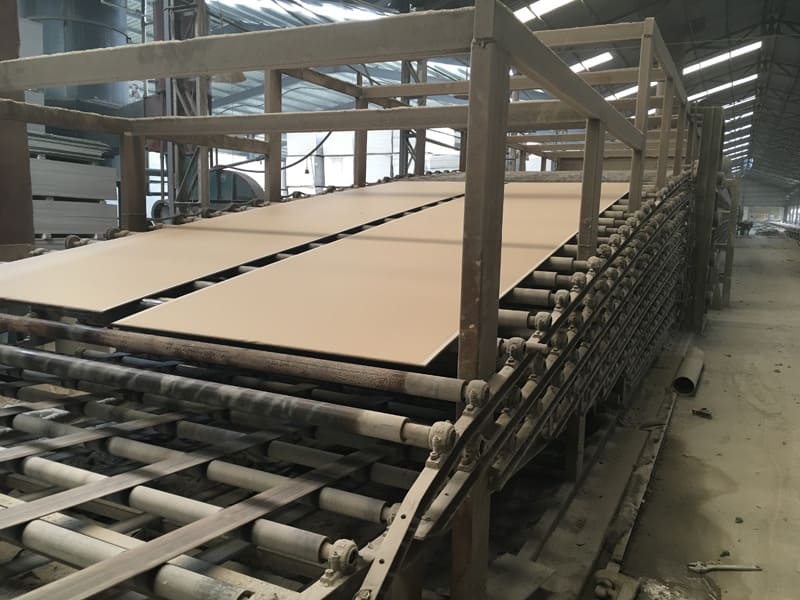

Recycled plasterboard undergoes processing where paper facing is separated from gypsum core, the gypsum is crushed and screened to remove contaminants, then calcined to produce calcium sulfate hemihydrate for new product manufacturing, creating a closed-loop system that reduces waste and conserves natural gypsum resources.

Paper separation occurs through mechanical processing removing paper facings from gypsum core material. Crushing and screening breaks down gypsum into specific particle sizes while removing metal fasteners and other contaminants. Calcination process heats recycled gypsum to remove water content creating calcium sulfate hemihydrate for new production. Quality control ensures recycled content meets manufacturing specifications for strength and purity. Closed-loop system reduces landfill waste and conserves natural resources.

Processing Stages

Recycled plasterboard processing involves multiple stages to ensure quality raw material recovery.

| Processing Stage | Purpose | Equipment Used | Quality Output | Efficiency Rate |

|---|---|---|---|---|

| Collection/Sorting | Separate clean material | Manual/automated sorting | Contaminant-free gypsum | 85-90% |

| Paper Removal | Strip facing materials | Mechanical strippers | Pure gypsum core | 95-98% |

| Crushing | Size reduction | Impact crushers | Uniform particles | 90-95% |

| Screening | Contamination removal | Vibrating screens | Clean gypsum | 92-96% |

| Calcination | Dehydration process | Rotary kilns | Plaster of Paris | 88-92% |

Paper removal achieves highest efficiency in recycling process quality control.

Material Recovery Rates

Different processing methods achieve varying recovery rates from recycled plasterboard.

| Recovery Method | Gypsum Recovery | Paper Recovery | Metal Recovery | Overall Efficiency | Processing Cost |

|---|---|---|---|---|---|

| Manual Separation | 70-80% | 60-70% | 50-60% | Low efficiency | High labor cost |

| Mechanical Processing | 85-92% | 80-85% | 85-90% | Good efficiency | Moderate cost |

| Advanced Automated | 92-96% | 90-95% | 95-98% | High efficiency | Higher investment |

| Mobile Processing | 80-88% | 75-80% | 80-85% | Site flexibility | Variable cost |

| Integrated Systems | 90-94% | 85-90% | 90-95% | Optimal efficiency | Justified cost |

Advanced automated systems provide optimal material recovery rates.

Environmental Impact

Plasterboard recycling significantly reduces environmental impact compared to landfill disposal.

| Environmental Factor | Landfill Disposal | Recycling Process | Impact Reduction | Sustainability Benefit |

|---|---|---|---|---|

| Greenhouse Gas | H2S emissions | Minimal emissions | 80-90% reduction | Climate protection |

| Resource Conservation | No recovery | Material reuse | 85-95% savings | Natural preservation |

| Landfill Volume | Direct disposal | Diverted waste | 90-95% reduction | Space conservation |

| Energy Consumption | Transport only | Processing energy | Net positive | Efficiency gain |

| Water Impact | Leachate risk | Controlled process | Pollution prevention | Water protection |

Recycling eliminates hydrogen sulfide emissions from landfill decomposition.

What Can You Do with Old Plasterboard?

Old plasterboard can be recycled into new gypsum products, used as soil conditioner for agriculture, processed into cement additive, donated for construction training programs, or properly disposed through certified waste facilities, with recycling being the preferred option for environmental and economic benefits.

Recycling through certified facilities provides optimal environmental benefit converting waste into raw materials for new manufacturing. Agricultural application uses crushed gypsum as soil amendment improving clay soil drainage and providing calcium nutrition. Cement production incorporates processed gypsum as setting regulator in concrete manufacturing. Educational donation supports construction training programs with practice materials. Proper disposal through licensed facilities prevents environmental contamination when recycling unavailable.

Recycling Options

Various recycling pathways offer different benefits for old plasterboard disposal.

| Recycling Method | Environmental Benefit | Economic Value | Convenience Level | Availability | Requirements |

|---|---|---|---|---|---|

| Manufacturer Take-back | High benefit | No cost/credit | High convenience | Limited areas | Clean material |

| Specialized Recyclers | High benefit | Processing fee | Moderate convenience | Growing network | Separation required |

| Construction Waste | Moderate benefit | Disposal fee | High convenience | Wide availability | Mixed acceptable |

| Agricultural Use | Moderate benefit | Potential value | Variable convenience | Rural areas | Contamination-free |

| DIY Processing | Variable benefit | Labor intensive | Low convenience | Self-managed | Equipment access |

Manufacturer take-back programs provide optimal recycling convenience and environmental benefit.

Preparation Requirements

Proper preparation maximizes recycling value and acceptance rates for old plasterboard.

| Preparation Step | Purpose | Method | Quality Impact | Recycler Acceptance |

|---|---|---|---|---|

| Contaminant Removal | Improve purity | Manual sorting | High impact | Required |

| Size Reduction | Transport efficiency | Breaking/cutting | Moderate impact | Preferred |

| Moisture Control | Prevent degradation | Dry storage | High impact | Critical |

| Fastener Removal | Eliminate metal | Magnet/manual | Moderate impact | Beneficial |

| Paper Separation | Increase value | Careful stripping | Variable impact | Sometimes required |

Contaminant removal critically affects recycler acceptance and processing efficiency.

Alternative Applications

Creative reuse options extend plasterboard lifecycle beyond traditional recycling.

| Alternative Use | Application Method | Durability | Cost Effectiveness | Skill Required |

|---|---|---|---|---|

| Garden Pathways | Crushed aggregate | 2-5 years | High value | Low skill |

| Compost Amendment | Ground additive | Permanent benefit | Moderate value | Low skill |

| Art Projects | Creative medium | Variable | Low cost | Variable skill |

| Training Material | Educational use | Repeated use | High value | Instruction |

| Base Material | Construction fill | Long-term | Moderate value | Moderate skill |

Garden pathway application provides immediate reuse value for homeowners.

What is Plasterboard Commonly Used For?

Plasterboard is commonly used for interior wall construction, ceiling installation, partition walls, fire-rated assemblies, and acoustic barriers in residential and commercial buildings, providing smooth surfaces for finishing while offering fire resistance, sound control, and easy installation characteristics.

Interior wall construction represents primary application creating smooth finished surfaces for paint and wallpaper. Ceiling installation provides level horizontal surfaces with integrated lighting and HVAC access. Partition walls enable flexible space division in commercial and residential applications. Fire-rated assemblies meet building code requirements for fire separation between spaces and floors. Acoustic applications control sound transmission through specialized board formulations and assembly techniques.

Application Categories

Plasterboard serves multiple construction functions across different building types and requirements.

| Application Type | Primary Function | Installation Method | Performance Requirements | Market Share |

|---|---|---|---|---|

| Interior Walls | Surface finishing | Screw fastening | Smooth finish | 45-50% |

| Ceilings | Horizontal surface | Suspended/direct | Sag resistance | 25-30% |

| Partitions | Space division | Stud framing | Structural stability | 15-20% |

| Fire-rated Systems | Fire protection | Specialized assembly | Fire resistance | 8-12% |

| Acoustic Barriers | Sound control | Dense installation | Sound attenuation | 5-8% |

Interior wall applications dominate plasterboard market usage.

Building Type Usage

Different building types utilize plasterboard for varying applications and performance requirements.

| Building Type | Primary Applications | Performance Priorities | Installation Volume | Specification Requirements |

|---|---|---|---|---|

| Residential | Walls/ceilings | Cost/appearance | High volume | Standard grade |

| Commercial Office | Partitions/ceilings | Flexibility/acoustics | Moderate volume | Enhanced performance |

| Healthcare | Fire-rated assemblies | Hygiene/safety | Specialized volume | Hospital grade |

| Educational | All applications | Durability/acoustics | High volume | Impact resistance |

| Industrial | Fire separation | Fire/moisture resistance | Limited volume | Specialized grade |

Residential construction represents largest plasterboard consumption sector.

Performance Characteristics

Different plasterboard types provide specific performance benefits for various applications.

| Performance Feature | Standard Board | Fire-resistant | Moisture-resistant | Sound-control | High-impact |

|---|---|---|---|---|---|

| Fire Rating | 30-60 minutes | 60-120 minutes | 30-60 minutes | 30-60 minutes | 30-60 minutes |

| Moisture Resistance | Limited | Limited | Enhanced | Limited | Limited |

| Sound Control | Basic | Basic | Basic | Enhanced | Basic |

| Impact Resistance | Standard | Standard | Standard | Standard | Enhanced |

| Cost Factor | Baseline | +20-30% | +15-25% | +30-50% | +40-60% |

Fire-resistant board provides optimal safety performance for protected assemblies.

Installation Systems

Plasterboard installation methods vary based on application requirements and structural conditions.

| Installation System | Structural Support | Fastening Method | Finish Requirements | Application Suitability |

|---|---|---|---|---|

| Direct Attachment | Existing structure | Screws/nails | Joint compound | Renovation/retrofit |

| Stud Framing | Metal/wood studs | Screw fastening | Tape/compound | New construction |

| Suspended Ceiling | Grid system | Clip attachment | Edge finishing | Commercial/office |

| Laminated System | Adhesive bond | Combined methods | Minimal joints | High-end applications |

| Curved Installation | Flexible framing | Specialized fastening | Complex finishing | Architectural features |

Stud framing systems provide standard installation method for most applications.

Conclusion

Recycled plasterboard serves multiple applications including new gypsum product manufacturing, agricultural soil amendment, cement production, and industrial uses, with processing involving paper separation, crushing, screening, and calcination to recover calcium sulfate. Old plasterboard options include recycling through certified facilities, agricultural application, cement additive use, educational donation, or proper disposal, with recycling preferred for environmental benefits. Plasterboard is commonly used for interior walls, ceiling installation, partition construction, fire-rated assemblies, and acoustic barriers in residential and commercial buildings. Success with plasterboard lifecycle management requires understanding that recycling creates closed-loop manufacturing systems, proper processing recovers high-quality raw materials, multiple reuse options extend material value, and primary applications focus on interior construction with varying performance requirements, making sustainable practices and appropriate application selection critical for environmental stewardship and construction quality in modern building systems.