Many people budget for drywall projects by only counting board prices. But accessories can consume half the budget if you overlook them.

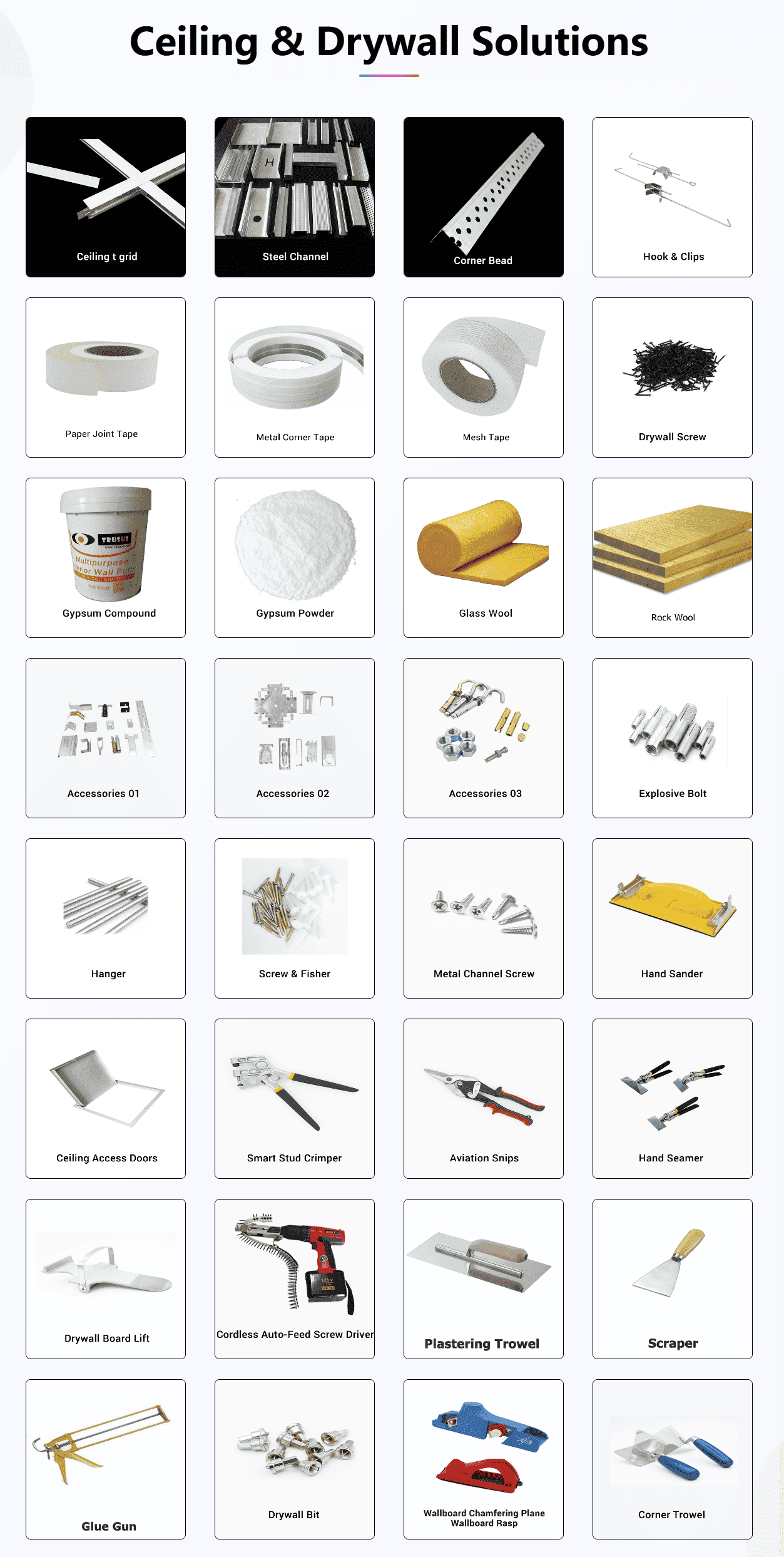

Drywall accessories include metal framing, fasteners, joint tapes, compounds, and finishing materials that support and complete gypsum board installations.

In my own work, I’ve seen accessories drive unexpected cost overruns. Light steel studs, suspension wires, expansion bolts, paper tape, self-tapping screws, and joint compound are basic necessities. Yet, their combined cost often reaches 40–60% of the total project price.

| Accessory Type | Function | Example Item |

|---|---|---|

| Framing components | Support and structure | Light steel studs, channels |

| Fasteners | Join boards to frames | Self-tapping screws, drywall nails |

| Joint treatment | Seam finishing | Paper tape, fiberglass tape |

| Finishing materials | Surface smoothness | Joint compound, skim coat |

| Support hardware | Ceiling hanging | Suspension wires, anchor bolts |

Good accessories ensure the build is strong, durable, and visually clean.

What is the drywall stuff called?

People often refer to all drywall materials as “the boards,” but the system has a more structured name.

Drywall “stuff” means gypsum boards and the complete accessory system, also called the drywall framing and finishing kit.

I’ve found that buyers mistakenly ask for “just the drywall” when ordering. In reality, a proper drywall construction package includes boards plus framing, fasteners, and finishing tools. Without them, installation cannot start.

| Term Used | Meaning | When to Use It |

|---|---|---|

| Gypsum board | The main drywall panel | Ordering base material |

| Drywall frame system | Metal studs and channels | Structural part of assembly |

| Finishing kit | Compounds, tape, sandpaper | Decorative and repair stage |

Knowing the proper names speeds up ordering and ensures suppliers provide complete systems.

What supplies are needed for drywall?

A common mistake in budgeting is listing only gypsum boards. Complete projects need a structured supply set.

Drywall supplies include panels, framing parts, connectors, adhesives, sealing materials, and surface finishing products.

On a recent hotel project, we used over 30 different types of supplies: various stud sizes, screws in multiple lengths, tape types, and sanding grits. The variety shocked the client during the procurement stage.

| Supply Category | Key Items | Purpose |

|---|---|---|

| Panel materials | Gypsum board, moisture-proof board | Wall and ceiling surface |

| Framing parts | Steel studs, channels | Holds drywall in place |

| Fasteners | Drywall screws, expansion bolts | Secure boards to frame |

| Joint finishing | Paper tape, compound | Smooth seams, prevent cracks |

| Sanding materials | Sandpaper, sanding sponges | Surface prep before painting or coating |

Listing all supplies in advance prevents mid-project delays or hidden cost spikes.

What are the names of drywall tools?

Drywall installation needs more tools than most homeowners realize. Skipping them makes the work slower and less precise.

Drywall tools include cutting, fastening, lifting, and finishing equipment designed for gypsum board construction.

I’ve invested over ¥20,000 in professional tools, from drywall lifts to dust control gear. For small contractors, spreading this cost across projects is essential.

| Tool Function | Example Tool | Benefit |

|---|---|---|

| Cutting | Utility knife, T-square | Clean, accurate board cuts |

| Fastening | Electric screwdriver, screw gun | Faster, precise screw placement |

| Lifting | Drywall panel hoist | Safe, effortless ceiling installation |

| Finishing | Putty knife, taping tool | Smooth joint treatment |

| Sanding | Pole sander, dustless sanding system | Clean, even surfaces before finishing |

Quality tools help achieve professional results and prevent costly rework.

Conclusion

Drywall success depends on the full system — boards, accessories, supplies, and tools — not just the panels. Ignoring these leads to hidden costs and lower quality.