Confused about studs and tracks in your drywall project? This common mix-up can lead to installation problems, structural weaknesses, and wasted materials.

The main difference between studs and tracks is their function: studs are vertical supports that hold the weight of the drywall, while tracks are horizontal channels that secure the studs at the top and bottom, creating a frame for the wall system.

When I first started manufacturing gypsum boards, I noticed many contractors struggling with the basics of framing systems. Understanding the difference between these components isn't just technical knowledge—it's essential for building safe, stable walls that last for decades.

What is a Drywall Stud and How Does It Work?

Pain point: Incorrect stud selection can lead to sagging walls, difficulty mounting fixtures, and even structural failures that compromise building safety.

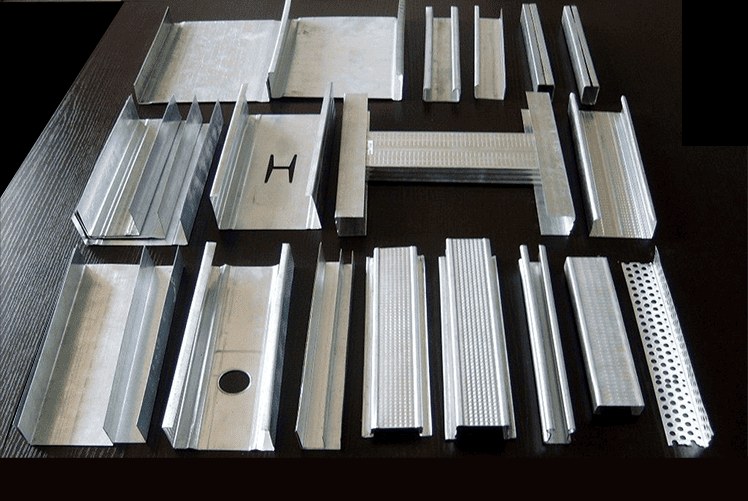

Drywall studs are vertical metal or wood members that form the main structural support for wall systems. Metal studs typically have a C-shaped profile with lips on the edges for strength, while wood studs are usually 2×4 or 2×6 dimensional lumber spaced 16 or 24 inches apart.

Studs are the backbone of any drywall installation. In my factory, we've tested various stud designs to understand their performance under different conditions. The key factors that determine a stud's effectiveness include:

Metal vs. Wood Studs: Which Should You Choose?

| Feature | Metal Studs | Wood Studs |

|---|---|---|

| Cost | Generally less expensive | Prices fluctuate with lumber market |

| Fire Resistance | Excellent (non-combustible) | Poor (combustible) |

| Moisture Resistance | Won't rot or warp | Susceptible to water damage |

| Weight | Lightweight | Heavier |

| Installation | Requires specialized tools | Familiar to most carpenters |

| Thermal Performance | Poor conductor (requires insulation) | Better natural insulation |

| Sound Isolation | Better with acoustic insulation | Less effective |

| Strength | Varies by gauge (thickness) | Generally stronger for heavy loads |

I've observed that most commercial projects now use metal studs due to their consistent quality and fire resistance. However, residential builders often prefer wood for its familiarity and ease of installation. The gauge of metal studs (typically 20-25 gauge) directly impacts their load-bearing capacity—lighter gauges for interior partitions and heavier gauges for load-bearing walls.

One crucial detail often overlooked: metal studs have pre-punched holes for electrical and plumbing runs, saving significant time during installation, while wood studs require drilling, which adds labor costs.

What Are Tracks and Studs Used For in Drywall Systems?

Many DIYers find themselves struggling with wobbly walls and uneven surfaces because they don't understand the proper relationship between tracks and studs.

Tracks and studs work together to create the framing system that supports drywall panels. Tracks are U-shaped channels installed horizontally at the floor and ceiling to house the vertical studs, creating a stable framework that distributes weight evenly and provides attachment points for drywall sheets.

Having supplied materials for thousands of construction projects, I've witnessed firsthand how crucial proper track and stud installation is for overall building performance. The track and stud system serves multiple critical functions:

Key Functions of Track and Stud Systems

Structural Support

Tracks and studs create the skeleton that supports not just drywall but also fixtures, cabinets, and in some cases, upper floors. The system must be engineered to handle both dead loads (the weight of materials) and live loads (people, furniture, etc.).

Wall Height and Stability

The gauge and spacing of studs determine the maximum practical height of a wall. For standard 8-10 foot residential walls, 25-gauge studs at 16" spacing are typically sufficient. However, commercial applications with higher ceilings may require 20-gauge or even 18-gauge studs with closer spacing.

Sound Isolation

Properly designed stud and track systems can significantly reduce sound transmission between rooms. Specialized configurations like staggered studs or double-track systems can improve acoustic performance by up to 60% compared to standard installations.

Fire Resistance

Metal studs and tracks contribute to fire-rated assemblies, which are critical in commercial buildings and multi-family housing. When combined with the appropriate type of gypsum board, these systems can achieve fire ratings from 1-4 hours.

In my experience, the most successful installations begin with careful planning of the track and stud layout, ensuring proper spacing (typically 16" or 24" on center) and correct alignment of studs. This meticulous preparation prevents costly issues like uneven walls or insufficient support for heavy fixtures down the line.

How to Tell Drywall vs. Stud During Installation and Repairs?

The frustration of hitting a stud when you intended to drill into drywall—or worse, missing a stud when you need structural support—is a common problem that leads to damaged walls and failed installations.

To distinguish between drywall and studs, use a stud finder for electronic detection, tap the wall and listen for a solid sound (studs) versus hollow sound (drywall), or measure 16" or 24" from corners where studs are typically placed. Visual clues include nail/screw heads and slight seam indentations on drywall surfaces.

After decades in the gypsum board industry, I've compiled reliable methods for identifying what's behind your walls. This knowledge is invaluable whether you're hanging a picture, mounting a TV, or planning a renovation.

Practical Methods for Locating Studs Behind Drywall

Electronic Detection

Modern stud finders use various technologies to detect density changes behind walls:

- Magnetic stud finders detect nails and screws in the studs

- Electronic stud finders measure density changes

- Advanced models can differentiate between wood studs, metal studs, and electrical wiring

These tools range from $10 basic models to $50+ professional versions with multiple sensors. In my testing, mid-range models ($25-35) offer the best balance of accuracy and value.

Manual Techniques

When electronic tools aren't available, several reliable manual methods exist:

-

Knocking Test: Tap along the wall horizontally. Drywall over studs produces a solid, dull sound, while hollow areas between studs create a resonant sound.

-

Electrical Outlet Method: Wall outlets are typically attached to studs on one side. Remove the cover plate and look to see which side the outlet is attached to. Measure 16" or 24" in either direction to find additional studs.

-

Baseboard Examination: Look for slight dimples or nail heads in baseboards, which indicate attachment points to studs.

-

Starting Corner: Studs are typically placed in corners and spaced every 16" or 24" from there. Measure from a corner and mark these intervals to find likely stud positions.

In renovation projects, I've found that walls in older buildings often have inconsistent stud spacing. In these cases, combining multiple detection methods provides the most reliable results. Remember that plumbing, electrical conduit, and ductwork can sometimes be mistaken for studs, so verification with small pilot holes is wise for critical installations.

Conclusion

Understanding the difference between studs and tracks is essential for successful drywall projects. Studs provide vertical support while tracks secure them horizontally, working together to create strong, reliable wall systems.